Important Information About Paint Finishes

For generations, people have determined that they love the look of painted cabinetry and furniture. However, as any woodworker can attest to, putting paint over solid wood is not necessarily a good idea when materials such as MDF are far superior for this purpose. This page is meant to educate our customers on the characteristics of painted solid wood as well as the benefits of MDF when painting. If you still determine that solid wood doors are what you desire, that is perfectly fine! We have done our job to educate and provide you with options. But…be aware that your sales rep will not be able to finalize your purchase until you have signed a statement of understanding as to the issues with painted wood and the limitations to warranty and replacements when it is used instead of MDF.

Please remember:

- Face frames on cabinets are still solid wood, even if an all MDF or Hybrid (solid wood frame with MDF center panel) door is requested. But, because the framing is so narrow, the corner cracking explained below is generally not near as pronounced.

- Not all doors Conestoga offers are available in all MDF construction. They offer about 50 of their most popular designs this way. Virtually all their doors have an MDF panel option though. This is called a ‘Hybrid’ door which has Paint Grade Maple framing and an MDF center panel. Your sales rep can guide you on the availability of MDF in the door design choices you are considering for your project.

The Problems With Painting Solid Wood

Hairline cracks:

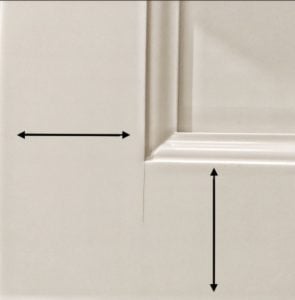

Wood is an organic material. It is constantly expanding and contracting as it takes on or gives off moisture. It is always seeking ‘equilibrium’ with its environment. Because wood moves and paint cannot, a natural tension persists for the life of the door. The framing on the door is comprised of 4 pieces of individual wood. The top and bottom ‘rails’ of the door have grain that runs left to right. The left and right ‘stiles’ of the door have grain that runs top to bottom. Because of this, these four pieces of wood are expanding and contracting in opposite directions. This creates natural stress at the joint where these pieces of wood meet. Since the paint is not ‘elastic’ enough to keep up with this wood moving below it, the paint is forced to give and it does so at the corner joint, splitting in a hairline right at the joint. See the image below for an example as it shows a normal hairline crack not covered under warranty, even if it came out of the package this way. The arrows in the image indicate the direction the wood wants to expand based on the orientation of its grain (which is opposite of the direction of expansion shown by the arrows).

It is important to understand that there is nothing Conestoga can do to prevent this from happening. When they leave the factory, the doors are at a moisture content of between 6.5 and 7.5% and the paint is not fractured. However, due to ambient humidity after the doors leave the factory, natural expansion or contraction can begin right away.

Offsets in framing:

Similar to framing cracks explained above, joint offsets can occur where the top and bottom rails expand beyond the ends of the vertical stiles. The last operation in the door making process is to edge profile the door and sand it. It will leave the factory perfectly flush. If you have offsets on the corners of your door where the top/bottom and left/right stiles meet, you can be assured you have a moisture-related issue. Remember, no door manufacturer can control wood movement due to moisture, so this is not considered a defect!

Panel lines:

Cabinet door panels are comprised of several individual pieces of wood (called ‘Staves’) all glued up edge-to-edge to create a wide panel. This use of many pieces of wood creates a stable panel that is less prone to warping, bowing or splitting. However, each piece of wood is unique. Each came from a different tree and each will respond to moisture differently due to its own density. Even the time of year that piece of wood was harvested (winter versus summer cut wood) can affect how it responds to moisture. As a result, once the cabinet door leaves the factory, the forces of moisture can make these individual panel staves swell at different rates and to different degrees. This creates vertical lines in the panel seams where these staves meet. This is not something Conestoga can control and is therefore not a reason for replacement.

Let’s look at an example of how the effects of moisture in a solid wood painted job may play out in a couple of situations:

Situation 1: “Bob and Kathy” live in Florida. They order their cabinetry in March and it arrives in early April. They open the doors and, since that winter was a cold and dry one in the Northeast (where the doors are made) in late winter, the doors did not pick up much moisture in transit, so all looks good, no corner cracks! They install their new cabinets. But March is a beautiful time of year in Florida so they have not needed to turn on their AC. Instead, they throw open the windows to let the nice Atlantic sea breeze cool the house naturally. This drives the relative humidity (RH) in their house sky-high. The doors immediately begin to pick up moisture, driving the moisture content (MC) up to 9 or 10%. They notice one day that several doors are ‘cracking’ at the corners, so they call CabinetJoint to file a warranty claim. The problem is, the joints are not ‘cracked’. The framing is completely intact and has not failed. The corners have simply experienced paint fracture and the warranty does not cover this.

Situation 2: “Frank and Mary” live in the mountains of Idaho. The order their cabinets in January. That winter was warm and very wet, so once the cabinets shipped, they crossed the country in a high humidity environment. Once the cabinets arrived, Frank put the cabinets in his garage for a week or two until he could begin assembly. While these cabinets sat, they sucked up moisture in the unheated garage, driving the MC up to 8%. Not hateful, so no corner cracks were evident yet. Frank finished the assembly and installed the cabinets. Mary likes a warm house, so they kept the wood stove hot all winter, enjoying the snowfall from the comfort of their nice warm mountain house. But the MC of the doors was driven back down to less than 6% by the now ultra-dry house. Boom…corner cracks appear on virtually all their doors. What’s more, they see vertical lines in their panels! They call CabinetJoint and request replacements, only to be told that this is normal and no replacements can be issued.

The point here is that you need to go into a painted wood door purchase with your eyes open to the issues that may/will affect your cabinetry. Conestoga’s adhesion tests exceed the KCMA standards by a wide margin. The issues described above are not a failure of the finish or the joint. They are a natural by-product of wood movement which cannot be controlled by any wood manufacturer and therefore, Conestoga cannot be held responsible for something they cannot control.

Some customers have commented that other painted wood products in their house did not crack when their new cabinetry did. Many variables can affect this, but one of the main things to understand is that new wood products have not yet ‘seasonalized’. Once a wood product is placed in its final environment, it undergoes a process of seeking equilibrium with its environment and after going through full hot/cold/wet/dry ‘seasons’ in the home, it gets much more stable and the issues described above become less common. So, just because the bathroom doors you installed 5 years ago did not have hairline cracks does not mean the new kitchen cabinets you just installed won’t or should not crack. There is no “crystal ball” that can be used to predict how a given job will be affected by a given environment.

The Superiority of MDF for Painted Solid Wood Doors

MDF gets a bad rap. The MDF used in premium cabinetry is not the same as the MDF you may be used to from the big box stores. It is denser, uses better adhesives, machines better, takes paint better and is more dent and impact resistant than any MDF you have probably been exposed to. It is definitely not the same material as you may be used to seeing in imported furniture which is not MDF at all, but more of a ‘particle board’ which uses much larger fibers and is not near as dense as MDF. Most importantly, MDF is stable and flat, exhibiting none of the issues of solid wood when painted. In fact, when a 5 piece door is made out of MDF (4 framing pieces and a center panel), you cannot tell it from a wood painted door…except in the fact that it stays looking the way you want it to! Let’s ‘bust’ some of the myths surrounding MDF in cabinetry:

Myth #1: It swells and blisters: This is true…only if you submerge the door in water. MDF is impervious to humidity, but standing water will blister the paint as the MDF literally acts like a sponge and soaks up the water. But, unless you plan on your house flooding, standing water is not a concern most people have in their kitchen considering the doors are at least 4″ off the floor. Much more insidious is airborne moisture/humidity which every house has and which wreaks havoc on solid wood products!

Myth #2: It won’t hold a screw: This is also somewhat true…but only if you don’t pre-drill. So long as you predrill the holes for your screw holes, a quality MDF will hold hinge screws as well as solid wood. And, if a screw pulls out, simply put a dab of epoxy in the hole and reset your screw (same repair process as with solid wood). A loose screw is really easy to fix whereas the above-mentioned issues with painted solid wood are not repairable and plainly visible for the life of your cabinetry.

Myth #3: It has an ‘orange peel’ effect in the profiled areas: This is true…but only if the MDF is not properly prepared prior to painting. Inferior cabinet makers will paint the MDF right after machining. The paint causes the MDF fibers to ‘stand up’ again, swelling with the paint’s moisture and creating the orange peel effect. Conestoga (and other quality cabinet makers) use a special glue sizing that is brushed into the machined edge, bead and panel areas of the door. Once dry, the profiles are sanded smooth and the glue holds the fibers down once painted. Conestoga calls this their ‘Prep and Seal’ option and it is standard on any painted MDF door. It is an option on unfinished MDF if the customer chooses to paint their MDF themselves. This option is why painted MDF doors are not generally much of a cost savings over solid wood.

Myth #4: It is more damage-prone and more difficult to repair chips and dings: This actually has no real truth to it. MDF is actually more dent-resistant on flat surfaces than solid wood! On sharp edges, MDF may be slightly easier to chip, but it is just as repairable. Truthfully, the edge profile is the most damage-prone area of the door and since most edge profiles have at least a slight radius (the edges are not ‘sharp’ 90-degree corners) they are really not much more likely to get dented or chipped than a solid wood door. If they do get chipped, MDF is just as easy to fill and repaint as solid wood is.

We often tell our customers that it with painted MDF being superior to wood in so many ways, it makes little sense to paint wood anymore. If you choose MDF and one or 2 doors do have some kind of issue, you are still better off repairing or replacing those few doors than dealing with the obvious and visible issues of solid wood for the length of time you own your kitchen. Why spend so much time and effort to ‘manage’ the issues with paint on solid wood when MDF was designed for this purpose? If you need more information on this topic, a simple google search has tons of it. Don’t just take our word for it! In fact, here is a helpful forum on Woodweb addressing this issue…